PCB BAsics

What type of board do I need?

Printed circuit boards come in various shapes, sizes, and materials. For basic boards, they can be broken down based on three different characteristics.

1. Size

2. Thickness

3. Number of Layers

4. Type of Material of Substrate

Size

The size of the board refers to the area of the board, for example 2 x 1 inches. The board area is normally given in inches or mils. This is fairly self explanatory. The board size is determined by the board outline or the smallest rectangle that circumscribes the outline. Some fabrication houses charge per board up to a certain size and others charge per square inch.

Thickness

Thickness is a little more complicated since a thickness is normally given in mils (in the USA). 1 Mil is 1 thousandth of an inch. If you confuse mil with mm or micron, you're gonna have a bad time! Standard boards come in various thicknesses such as 20, 31, 62, 93, 125 mil depending on which fabrication house you use to create your boards. Make sure you use a standard size to keep costs down unless you need a specific geometry for a design purpose.

Layers

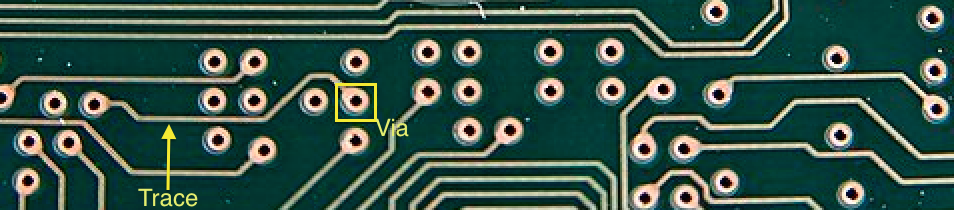

Layers are, as you would expect, stacked together to form the PCB thickness. Each layer uses copper to make connections and also has a substrate that the copper is mounted on for stability. The top layer of a PCB is shown in the picture has a bunch of traces connecting to vias which are holes that connect layers to each other. Layers and vias are very important to understand for layout.

Material

The last characteristic of PCBs is the material of the substrate. Most common substrates are dielectrics. The cheapest (in general) and most common substrate is called FR-4. FR-4 is made of fiberglass epoxy resin. If there are no antennas or high frequency circuits on your board, the material and thickness of each layer have very little effect and do not have to be designed for.

Printed circuit boards come in various shapes, sizes, and materials. For basic boards, they can be broken down based on three different characteristics.

1. Size

2. Thickness

3. Number of Layers

4. Type of Material of Substrate

Size

The size of the board refers to the area of the board, for example 2 x 1 inches. The board area is normally given in inches or mils. This is fairly self explanatory. The board size is determined by the board outline or the smallest rectangle that circumscribes the outline. Some fabrication houses charge per board up to a certain size and others charge per square inch.

Thickness

Thickness is a little more complicated since a thickness is normally given in mils (in the USA). 1 Mil is 1 thousandth of an inch. If you confuse mil with mm or micron, you're gonna have a bad time! Standard boards come in various thicknesses such as 20, 31, 62, 93, 125 mil depending on which fabrication house you use to create your boards. Make sure you use a standard size to keep costs down unless you need a specific geometry for a design purpose.

Layers

Layers are, as you would expect, stacked together to form the PCB thickness. Each layer uses copper to make connections and also has a substrate that the copper is mounted on for stability. The top layer of a PCB is shown in the picture has a bunch of traces connecting to vias which are holes that connect layers to each other. Layers and vias are very important to understand for layout.

Material

The last characteristic of PCBs is the material of the substrate. Most common substrates are dielectrics. The cheapest (in general) and most common substrate is called FR-4. FR-4 is made of fiberglass epoxy resin. If there are no antennas or high frequency circuits on your board, the material and thickness of each layer have very little effect and do not have to be designed for.

Vias

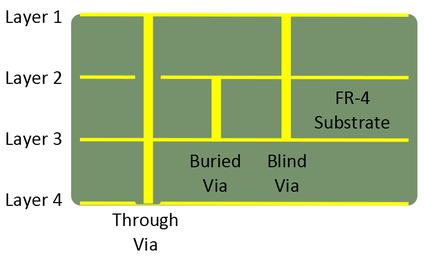

Vias connect layers to other layers with copper to make layout easier and fit circuits on a smaller size board. There are three types of vias but you should only ever use one (for beginners).

Through Via - This is one you should use. The fabrication house will drill a hole through the entire board and plate the entire hole with copper. In the picture, Layer 1 and Layer 3 are connected while Layer 2 and Layer 4 are isolated from the via. Your board can have a ton of these before you get charged extra.

Buried Via - Buried vias connect two internal layers without drill holes on the outer layers. These are very expensive for fabrication houses, since they must drill the inner layers then epoxy them to outer layers.

Blind Via - Blind vias should also not be used for most cases. They are similar to buried vias except that one side connects to an outer layer. They can dramatically increase the cost of a cheap board.

Vias connect layers to other layers with copper to make layout easier and fit circuits on a smaller size board. There are three types of vias but you should only ever use one (for beginners).

Through Via - This is one you should use. The fabrication house will drill a hole through the entire board and plate the entire hole with copper. In the picture, Layer 1 and Layer 3 are connected while Layer 2 and Layer 4 are isolated from the via. Your board can have a ton of these before you get charged extra.

Buried Via - Buried vias connect two internal layers without drill holes on the outer layers. These are very expensive for fabrication houses, since they must drill the inner layers then epoxy them to outer layers.

Blind Via - Blind vias should also not be used for most cases. They are similar to buried vias except that one side connects to an outer layer. They can dramatically increase the cost of a cheap board.

Copper Thickness

Most PCBs use copper for the traces, vias, and planes for ease of use and low cost. When discussing the thickness of copper, it may be confusing at first because it is normally discussed as a mass. For example, most PCBs use 1 oz copper. This means that 1 oz copper is used over 1 square foot area which results in a thickness. For your convenience, I list some copper thicknesses below. You only have to memorize 1.37 mils = 1 oz Cu and the others can be calculated easily! For low power circuits, the copper thickness does not matter much, but let's say you are trying to draw 1 A through a trace. Make sure your have sufficiently thick copper to handle that. This will be discussed in more detail during layout.

Most PCBs use copper for the traces, vias, and planes for ease of use and low cost. When discussing the thickness of copper, it may be confusing at first because it is normally discussed as a mass. For example, most PCBs use 1 oz copper. This means that 1 oz copper is used over 1 square foot area which results in a thickness. For your convenience, I list some copper thicknesses below. You only have to memorize 1.37 mils = 1 oz Cu and the others can be calculated easily! For low power circuits, the copper thickness does not matter much, but let's say you are trying to draw 1 A through a trace. Make sure your have sufficiently thick copper to handle that. This will be discussed in more detail during layout.

| Mass | Thickness |

|---|---|

| 1 oz Cu | 1.37 mil |

| 2 oz Cu | 2.74 mil |

| 3 oz Cu | 4.81 mil |

Gerber Files

Gerber files are files for fabrication houses to manufacture your PCB. These files carry information about where there is copper and where there is not copper as well as where to drill holes. The various files required for a 2 layer board are as follows:

1. Top Copper - Location of where the copper is and where it is etched away by a chemical or mechanical process on the top layer

2. Bottom Copper - Location of where the copper is and where it is etched away by a chemical or mechanical process on the bottom layer

3. Top Soldermask - An insulating cover that helps protect top copper traces from oxidizing (normally light green on your circuit board)

4. Bottom Soldermask - An insulating cover that helps protect bottom copper traces from oxidizing (normally light green on your circuit board)

5. Top Silkscreen - Superficial layer of text on the top layer (normally white text on green PCB)

6. Bottom Silkscreen - Superficial layer of text on the bottom layer (normally white text on green PCB)

7. Board Outline - Outline of the entire board (normally a rectangle even for non-rectangular boards)

8. Drill file - Location of all drill holes and drill diameters for the entire circuit board

Most fabrication houses accept these files zipped up into a single file and return to you a pdf of each Gerber file, so you know exactly what the fabrication house plans on making. This is a way to confirm that the order is put in correctly.

Gerber files are files for fabrication houses to manufacture your PCB. These files carry information about where there is copper and where there is not copper as well as where to drill holes. The various files required for a 2 layer board are as follows:

1. Top Copper - Location of where the copper is and where it is etched away by a chemical or mechanical process on the top layer

2. Bottom Copper - Location of where the copper is and where it is etched away by a chemical or mechanical process on the bottom layer

3. Top Soldermask - An insulating cover that helps protect top copper traces from oxidizing (normally light green on your circuit board)

4. Bottom Soldermask - An insulating cover that helps protect bottom copper traces from oxidizing (normally light green on your circuit board)

5. Top Silkscreen - Superficial layer of text on the top layer (normally white text on green PCB)

6. Bottom Silkscreen - Superficial layer of text on the bottom layer (normally white text on green PCB)

7. Board Outline - Outline of the entire board (normally a rectangle even for non-rectangular boards)

8. Drill file - Location of all drill holes and drill diameters for the entire circuit board

Most fabrication houses accept these files zipped up into a single file and return to you a pdf of each Gerber file, so you know exactly what the fabrication house plans on making. This is a way to confirm that the order is put in correctly.